ALTERNOVA is a multidisciplinary optimization software platform intended for the design and sizing of complex systems (products and industrial processes) in a digital environment.

The challenges faced

Research into optimal designs is performed by experimental design and multi-criteria optimization. Yet, the numerical simulations required to appraise the designs tend to require too much computing time to be used in optimization algorithms.

Therefore, Eurodecision in partnership with RENAULT has developed the ALTERNOVA multidisciplinary optimization software platform in which simulations are replaced by system observable estimating functions (response surfaces) that will be exploited and improved by applying an iterative optimization approach.

The experimental design tests are used to initialize these response surfaces. Afterwards only the optima proposed by the optimization algorithms are validated by the numeric simulators and their results used to improve the estimate quality for the following optimization iterations.

System validation can call for a variety of disciplines, and thus potentially different numerical simulation codes. The design problems are heavy multi-criteria, large-scale non-linear optimization problems. Solving these problems gains from incorporating the experts’ “business” preferences to guide exploration of the space in areas initially viewed as interesting.

Alternova business applications:

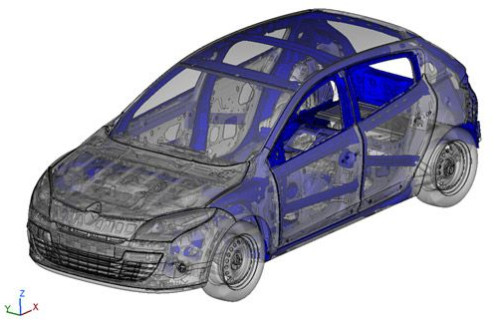

- to facilitate roll-out of ALTERNOVA and the associated methodology in operational divisions, we have designed dedicated applications for specific business issues. For example, in the automotive field, there is an application to design hood linings, another to reduce body weight under crash and vibratory constraint, and so on. They let field experts who are neither optimization nor statistics specialists implement mainstream studies

- they are provided with graphic interfaces to determine the scope of their study (the design parameters and their variation intervals) and specifications on the observables of the digital model

- the calculation processes are automated (calculation simulator call-up, pre- and post-processing); the latter may be complex if allowance is made for shape modifications (configured CAD, automatic meshing)

- the experimental design plan and optimization algorithm choices are configured as befits the problem being handled

- the results analysis on all the criteria is made simpler for the purpose of selecting the best compromises

- sequencing of various stages in the optimization methodology is automatic.

Why choose our component?

ALTERNOVA helps you improve your products, systems and industrial processes’ performance levels. For example:

- by reducing the weight of vehicles while complying with standards and specification constraints

- by minimizing your systems’ energy consumption and pollutant emissions,

- by identifying design factors to get a better grasp of your systems’ behavior patterns

- by highlighting potential faults in your designs to make them more robust

- by reducing design cycle times, by automating numerical simulations and searching for a systematic solution using optimization methodology by experiment design.

With ALTERNOVA you can capitalize on the experience acquired on studies of the same kind within a business application. This acquired expertise will be circulated more easily through operational divisions.

Main features

The ALTERNOVA platform has a number of constituent modules:

- Experiment designs: a library of experiment designs, constraint test generation, D or G-optimal selection, and so on.

- Response surface building: least squares regression, Polymars, Lolimot, Kriging, expert mixtures, and so on

- Response surface improvement: quality analysis, test generation for improving response surfaces

- Optimization: multi-criteria strategies, simulated annealing, gradient, evolutionary algorithms (NSGA-II), and so on

- Test selection: MaxiMin, D or G-optimal design complement, ELECTRE III, ELECTRE RANKING and so on

- Solutions analysis: constraint overshoot report generation, visualizing Pareto fronts, interactive and graphic data filtering, factor influence analysis (Morris, Sobol, etc.)

- Robust design: use of OPEN TURNS.

The fruit of collaboration with RENAULT:

The ALTERNOVA software suite, which is the fruit of collaboration between RENAULT and Eurodecision, is used by RENAULT and NISSAN to help in vehicle design. Many studies have been carried out: reducing the weight of vehicle bodies in white, reducing the weight of parts or sub-assemblies (hood linings, nozzles, shock absorbers, seats, and so on) recalibrating numerical models (thermal studies of vehicle lights, recalibrating laws of materials), design of a chassis cross-member and analysis of the major parameters, analysis of the strength of a car body during a head-on crash, aerodynamic study of disk brakes, underbody, instrument panel fastenings, sizing of an electric traction chain and so forth.